Predictive Maintenance

Pioneering Predictive Maintenance: Our Digital Twin Solution for Hydraulic Systems

At BOA Hydraulics, we are dedicated to pushing the boundaries of innovation to address difficult hydraulic industry challenges. One of the most recurring challenges our clients experience is the unpredictable failure of hydraulic hoses due to wear and tear, which causes major operational and financial disruptions. The absence of trustworthy data on hydraulic hose lifespan, combined with the numerous factors impacting their endurance, has long hampered optimal asset care and management.

Recognizing the gravity of this situation, our team has spent the last two years designing a breakthrough solution that leverages digital technologies and big data analytics. We are excited to reveal the concept for our latest project, a digital twin platform for hydraulic assets. Our approach promises to transform the way hydraulic systems are maintained by providing an accurate digital replica of each hydraulic asset.

This digital twin functions as a comprehensive storehouse for all important data, including:

- Asset Specifics: Details on the asset's brand, age, and usage hours, providing a comprehensive context for each hydraulic system.

- Hose Placement and Environment: Data on each hose's location within the asset, as well as external environmental conditions, taking into account the impact of physical placement and weather on hose durability.

- Maintenance History: Detailed records of reactive maintenance, such as the bill of materials for replaced hoses, the type of repairs, and the operational hours during the maintenance period.

By integrating this vast amount of data, our digital twin platform not only archives prior maintenance activities but also dynamically updates with each hose replacement. This constant data enrichment enables precise tracking of each hose's lifespan inside the system.

Our innovation is centered on the application of big data analytics to this large dataset. By studying trends and patterns, our technology can anticipate each hose's remaining useful life, allowing for preventive maintenance decisions. This predictive capability is intended to shift maintenance tactics from reactive to preventative, therefore considerably lowering downtime and associated costs.

While we are still in the early phases, the potential for this technology is enormous. As more data accumulates and our algorithms improve their prediction accuracy, we expect a paradigm shift in hydraulic asset management, with hose failures expected and prevented rather than simply reacted to.

This initiative is a huge step forward in our efforts to improve the reliability and efficiency of hydraulic systems. While the full potential of its predictive and preventative capabilities may be years away, the foundation we are laying today will pave the road for a more sustainable, cost-effective, and safe future in hydraulic system maintenance.

At BOA Hydraulics, we are shaping the hydraulic industry's future rather than just inventing for the present. Stay tuned for additional updates on this exciting journey to a smarter, more resilient hydraulic ecology.

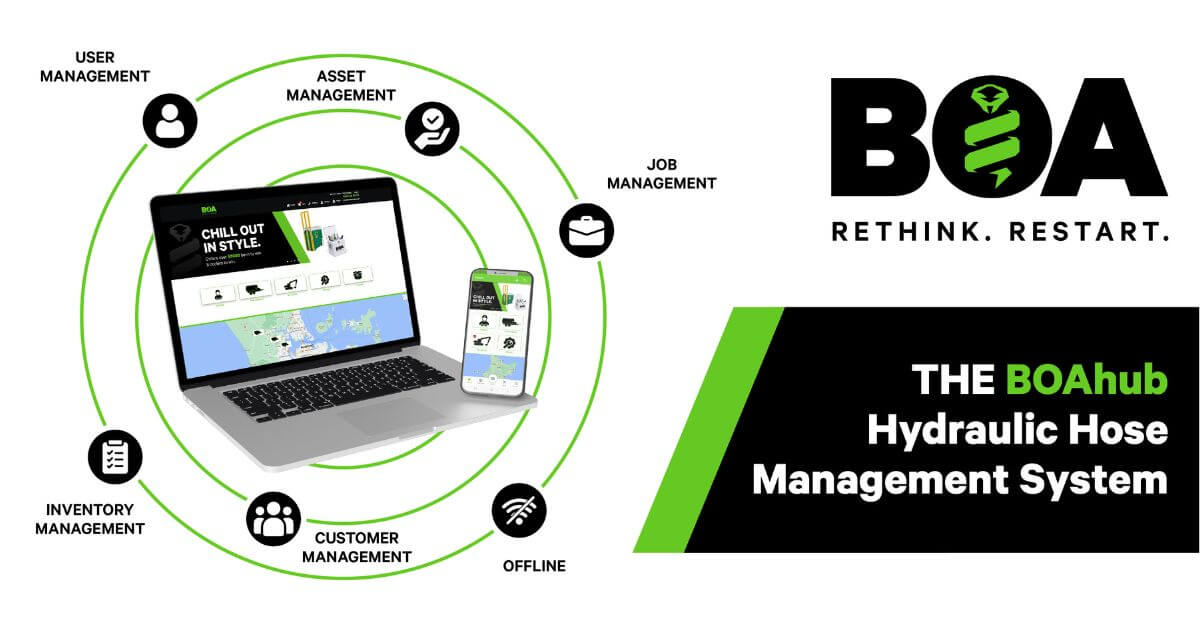

Learn more about the BOAhub.