What is Hydraulic Uptime and why is it important?

Learn what is hydraulic uptime and why is it important.

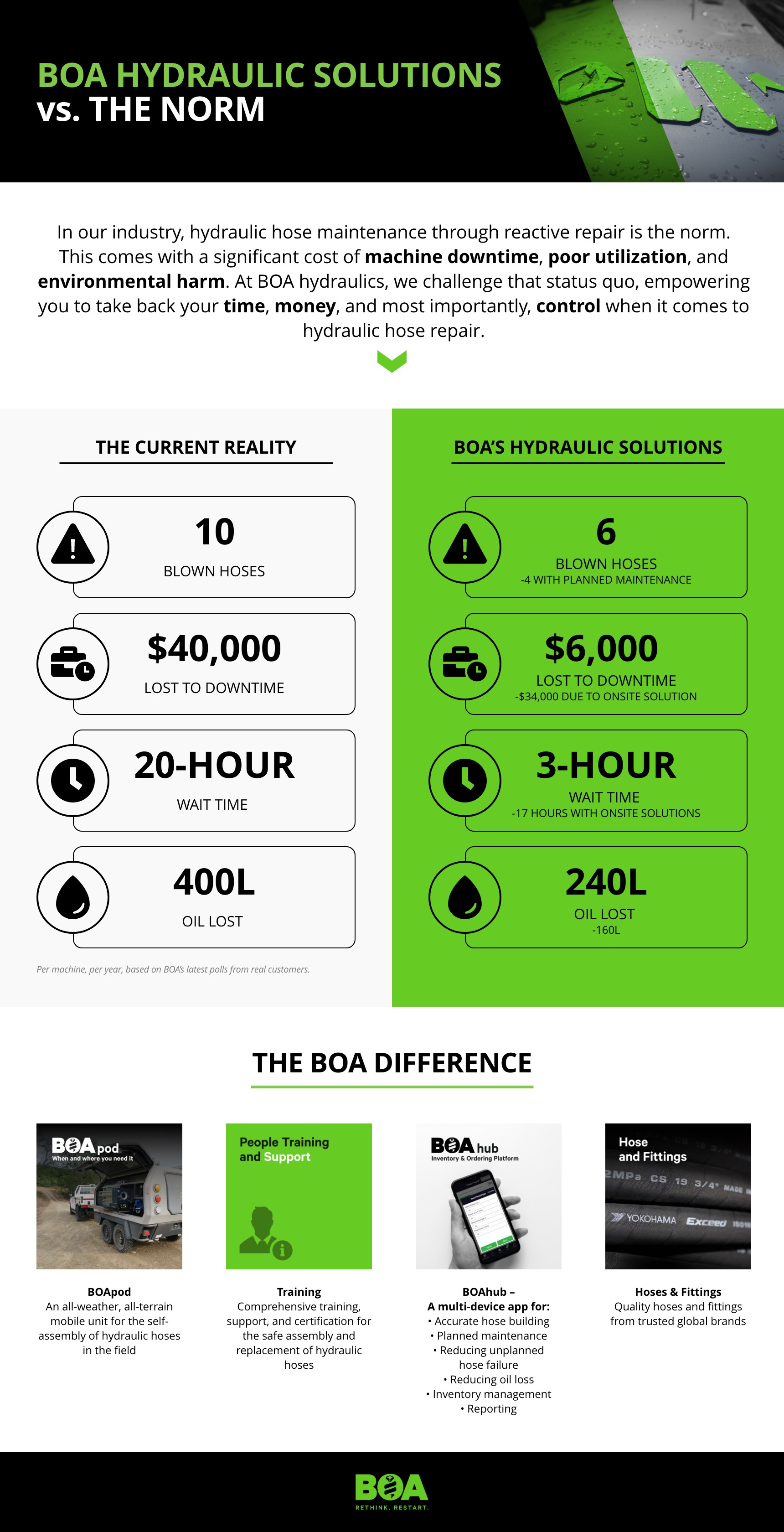

Find out about the cost of hydraulic downtime and why increasing hydraulic uptime is so important for heavy equipment users. Businesses in civil construction, forestry, demolition, quarrying, mining, and other heavy equipment industries know all too well that hydraulic hose failure can mean hours on the job lost to downtime.

Losing time comes with a substantial cost to the project, not to mention the callout and repair expenses for fixing hydraulic hoses with a third-party contractor.

It’s therefore important for heavy equipment users to focus on how to increase their ‘hydraulic uptime,’ as doing so means increasing the productivity and profitability of their assets, giving them greater autonomy and control.

What is hydraulic uptime?

Hydraulic uptime is the process of converting downtime experienced by hydraulic hose failure on heavy machinery into operational hours, thereby increasing:

- the productivity of the machine

- the profitability of operational business hours.

With some forward planning, and greater awareness of the support available for heavy equipment users, companies and contractors can achieve hydraulic uptime and drastically reduce operational costs.

Hydraulic downtime is costing companies time, money, and oil

According to the University of Wollongong in Australia, 37% of unscheduled downtime on a hydraulic machine in mining is due to hydraulic hose failure. This percentage can vary between industries, and between individual companies based on the number of assets in operation and their site location.

When heavy equipment users experience unplanned downtime due to a blown hose, operations stall. Depending on the site location, it can take hours – or even days – to have the machine fixed and operational again. When experiencing downtime like this on a front-line machine, the real cost to the business is many times the actual cost of the hose repair.

In addition to lost time, blown hoses also result in oil spillages, which is an additional financial and environmental cost.

Presently, many heavy equipment users take a ‘reactive’ approach to their hydraulic hose repair and maintenance; when a hose blows, they stop operations and wait for the hose to be fixed. This is a key obstacle to achieving hydraulic uptime.

Just as we schedule maintenance for our cars to eliminate unplanned breakdowns, companies should practice proactive maintenance when it comes to their hydraulic machinery. By developing a proactive attitude towards hydraulic assets, companies can reduce their downtime by up to 85% - saving time, money, and oil, and getting greater use out of their machines.

How can companies and contractors achieve hydraulic uptime?

Companies can achieve greater hydraulic uptime by giving companies and contractors the right tools, training, and support to manage their hydraulic hose repair and maintenance.

To increase hydraulic uptime, companies must first gain an appreciation for their current downtime costs. The BOA Uptime Calculator is a free, easy-to-use tool that will help heavy equipment users understand how much time, money and oil, their downtime is costing them.

Once heavy equipment users are aware of how much downtime costs them in terms of time, money, and oil, it’s important to then consider:

- How to take control of that downtime with an immediate, onsite hydraulic hose repair solution

- Which experts in the local area are best equipped to respond to hydraulic hose needs

- How to schedule and manage hydraulic maintenance to ensure minimal disruptions to operations and time lost on the job.

Companies with a large number of hydraulic assets or situated in remote locations could significantly reduce their downtime and hose bills with an onsite mobile hydraulic hose self-repair and maintenance facility. Once fully trained, these crews can become totally self-sufficient in repairing their own hoses.

Smaller businesses and contractors with fewer assets would also benefit from seeking out the most cost-efficient and comprehensive service providers in their local region who are available, responsive, and sensitive to the needs of heavy equipment users. Providers that offer full mechanical engineering and hydraulic hose repair services can accurately troubleshoot mechanical issues that may be contributing to hydraulic hose failure. Not only do they have the tools and knowledge to replace the hose, but they can fully service the machine and help businesses achieve greater hydraulic uptime.

Finally, it’s important to let technology do some of the work. Companies can manage the lifecycle of their hydraulic hoses and better manage their assets with the appropriate digital solution that automates processes such as ordering parts, remembering common hose recipes, as well as seamlessly accessing qualified hydraulic hose service providers.

.jpg)

BOA Hydraulics’ integrated solution

Hydraulic uptime is a key pillar to achieving greater profitability from heavy machinery assets through appropriate hydraulic hose repair and maintenance.

With the BOA integrated solution, we pay attention to the full lifecycle of hydraulic hoses. We’ll ensure companies have the tools to save time, money and oil with:

- The BOApod: a mobile, state-of-the-art hydraulic hose facility for the self-assembly of hydraulic hoses in the field

- Comprehensive training and support for the safe assembly and replacement of hydraulic hoses by your crew members

- The BOAhub: a multi-device app for accurate hose building, planned maintenance, reducing unplanned hose failure, reducing oil loss, inventory management, and reporting

- Top quality hoses and fittings: quality products from trusted global brands, including Yokohama, Uniflex, and DNP.

With this integrated hydraulic hose repair and maintenance solution, BOA customers have been able to reduce their hose bills by as much as 60%, making significant savings and achieving greater hydraulic uptime on their assets.

Contact BOA Hydraulics to achieve hydraulic uptime

At BOA Hydraulics, we’re helping companies turn their wasted time back into profit. We do this by reducing downtime by up to 85%, lowering the costs of hydraulic hose bills and reducing oil spillages onsite.

To find out more about our integrated hydraulic hose repair and maintenance solution, contact the BOA Hydraulics team today.

We’ll provide a personalized solution for your business so you can achieve greater hydraulic uptime.