Increase Productivity through Increase Efficiencies

Increased efficiency is caused by increasing your productivity. Start with what you know and see if it can be tweaked, added to, or refreshed as required. We have also identified where efficiencies could be made with your hydraulic hose repair & maintenance.

How to Increase Efficiency by Increasing your Productivity

As businesses around the country and the world cope with lockdowns and a decrease in the supply of goods, identifying efficiencies to combat these obstacles becomes a key focus. It means doing more with less, working smarter, and not necessarily harder.

Finding ways to increase efficiencies does not mean you have to start from scratch. It means you need to start with what you know and see if it can be tweaked, added to, or refreshed as required.

At BOA Hydraulics our overarching message is “Turn Wasted Time Into Profit”, this is based on the premise that we give people the ability to roll up their sleeves and get on with it, instead of having to ‘down-tools’ and wait for it to be fixed, costing time and money.

With this in mind, it is imperative to understand what is causing wasted time in your business and where efficiencies can be made. Utilizing innovation, technology, and training combined with a review of all your current processes and procedures, can not only increase efficiencies but also reduced health and safety concerns across the business.

Consider the following when identifying where efficiencies could be made with your Hydraulic hose repair and maintenance:

Review the costs of hydraulics repair, maintenance, and management across your fleet.

- Take the time to review your hydraulics repair processes and challenge the efficiency of each step. Think about any wastage in your processes such as unnecessary movements of plant, product, and people.

- Consider not only the financial costs, like onsite subcontractors and hose and fittings, but also the cost of downtime, underutilised staff and delays in contract or project completion.

- Often forestry and civil contractors operate with a reactive hydraulics repair model; many wait until a hydraulic hose blows onsite to halt operations, call a hydraulic hose technician - who may be located far from the site - and wait for the repair. Consider how you maintain your expensive hydraulic machinery; what triggers a repair and any health and safety implications.

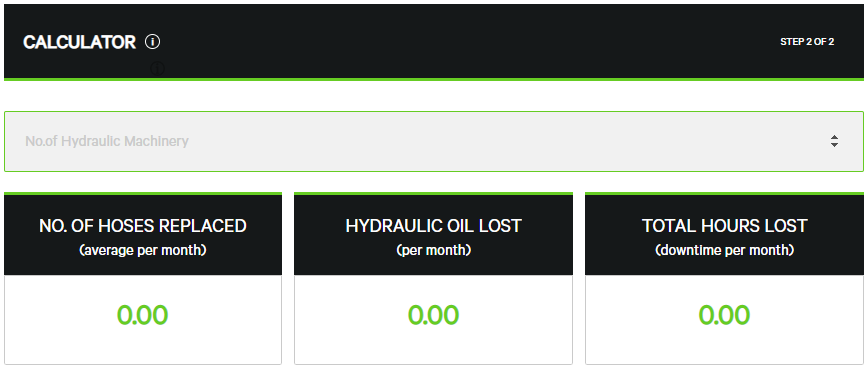

Unsure how much your hydraulic downtime is really costing you? The BOA Uptime Calculator can help you understand how much your hydraulic hose repairs are costing you in terms of downtime, callout and replacement fees, and oil loss.

Organise and Optimise your Staff Capabilities

- Take the time to analyse the capability within your current team and assess what training might be required to up-skill, so they can take care of your hydraulic repair and maintenance.

- Talk to BOA about what training might be involved and whether a staff member could service multiple sites.

- Consider how this could be an efficient use of staff during downtime and the intrinsic value of higher-skilled staff.

- Assign a qualified team member to provide additional training to the wider team as to what to look for when assessing hydraulic hoses for damage or wear and tear. This brings about great efficiencies in preventative hydraulic maintenance; leading to fewer blown hoses and reduced downtime.

- Optimise staff training with Health and Safety training including how to deal with hydraulic hoses under pressure. This all leads to more productivity, efficiency, and a safer worksite for you and your team.

Implementing efficiencies is never easy but this should not stop you from making changes and trying new ways of streamlining your operations. With increased efficiencies in your business, you can also turn wasted time into profit.